Operators of tank farms and terminals face various challenges in an ever changing environment: handle highly valuable products safely and efficiently, track capacity and turnovers, monitor quality, prevent overfill, and reduce loading and unloading times

To ensure a long-term competitive advantage, processes need to be flexible and expandable to adapt to new or changing conditions easily. Furthermore, a high standard of safety is required to reliably protect people, environment, and assets.

In such a situation, having reliable and modern measuring instruments, software and solutions help both, Owners and Operators of Storage facilities to reduce inventory costs, improve customer satisfaction and increase productivity. An important aspect of the complete operations is availability of high-quality online and real time data which will aid in effective decision making.

Here we see some of the Measurement Solutions for Storage, Inventory Management and Bunkering operations for all kinds of Bunker Fuels from Heavy Fuel oil (HFO), Marine Gas Oil (MGO) to Liquified Natural Gas (LNG) that Endress+Hauser has to offer.

Storage and inventory management solutions

In times where a wealth of data is available, businesses often still lack the right information. From simple monitoring and visualisation of tanks and silos up to highly accurate tank gauging and inventory monitoring on a global scale, our solution for inventory monitoring guarantees complete inventory visibility 24 hours a day, seven days a week, anywhere in the world. Inventory monitoring solutions allow you to make transparent business decisions.

Endress+Hauser also supports in the optimisation of supply chain with individual software solutions for inventory management and the integration of this data into the ERP systems seamlessly.

LNG storage tank gauging

From the day of an LNG tank being commissioned, it may be years before it comes out of service. For safe operations and optimum availability, a typical LNG tank will have a wide range of measurement instruments to measure liquid level, liquid density, liquid and vapour temperature, liquid and vapour pressure, skin temperature and much more. Typically, each tank would be fitted with two level gauges configured as a primary and a secondary, and an alarm Gauge. In addition, there would also be an LTD gauge for density profile measurement.

The primary and secondary gauges can be either servo and/or radar operated units also mounted on the tank roof. The purpose of these gauges is to provide continuous liquid level measurement, and average liquid temperature measurement. They provide redundancy on the measurement of level and temperature. The average liquid temperature is derived from a multi-point temperature sensor device.

The alarm gauge is often a servo or radar-based gauge configured to provide volt free contact alarm status to an independent system. The alarm gauge is often connected to the LNG tank management system so that its operational status can be monitored.

The LTD gauge is a servo operated unit mounted on the tank roof. The purpose of the LTD gauge is to take accurate profiles of temperature and density throughout the liquid, and whilst not profiling provide continuous liquid level, temperature, and density measurement.

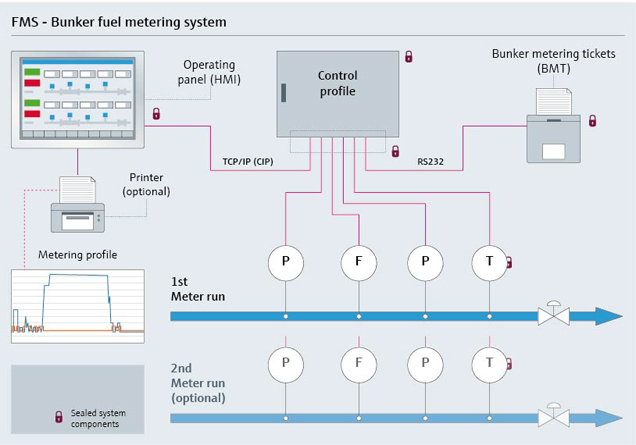

Bunkering metering system

Ship owners and barge operators have been increasingly installing special bunker fuel metering systems that ensure transparent and highly accurate bunkering. These systems contain Coriolis flow meters (MFM – Mass Flow Meter), which have been tried and tested for decades in custody transfer applications. Even certain port authorities have stipulated these measuring systems for Bunkering operations at their ports under strict control. Endress+Hauser has over 250 installations worldwide on various barges and vessels.

Advantages of using a Mass Flow meter based Bunker Metering System

-Ease of Operation

-Gains in efficiency

-Better Process Transparency

-Improved measuring accuracy

-Historical Data Storage – Audit Trail possible

-Safety

For LNG bunkering, Endress+Hauser can not only provide the metering systems but also Raman Analyzer which provides in-line real time composition of the Liquified Natural Gas (LNG). This is a unique offering from Endress+Hauser.

-By Apurva Sharma, Team Leader - Industry Management.