Through its M&J Valve brand, Celeros Flow Technology has developed a patented surge relief solution that reacts to unexpected pipeline pressure surge events in a rapid and efficient manner

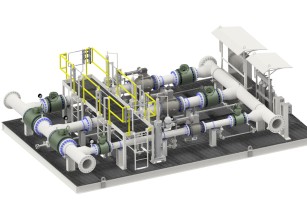

This solution integrates the DANFLO surge relief valve into a fully skidded surge relief system that provides protection against dangerous pressure spikes in piping systems and pipeline surges. DANFLO Series Surge Relief Valves are rated ANSI 150-900 and essentially comprise a dynamically balanced plug assembly that slides back and forth easily to rapidly open, close and throttle.

DANFLO valve technology is used in the M&J Valve rate-of-rise surge relief system. This innovative design combines a surge pressure relief valve with a predictive pressure rate-of-rise system to allow preventive action against a developing surge event.

To predict the rate of rise of the system pressure, the M&J Valve surge relief solution utilises a differential pressure pilot valve. This additional pressure control is constantly monitored and, upon reaching a pre-set limit, will trigger the main surge relief valve to open. As the surge dissipates, the valve closes without slamming shut, preventing ‘chatter’ or creation of additional surges.

The complete circuit is mechanical and provides a reliable hydraulic safety barrier against transient pressure surges. Because it uses no electronic devices, the M&J Valve surge relief system stand-alone solution is not affected by power loss, communication disruption, or cyber-attacks: making it far less vulnerable to external factors. The system not only reacts swiftly to high pressure surge waves to minimise risks of the process exceeding the maximum allowable operating pressure, but more importantly it continuously monitors the rate of pressure rise in the system.

In addition, its high-flow capacities mean that smaller and/or fewer valves are used, which saves on installation costs and weight. A set-pressure test port makes it easy to comply with regulatory testing requirements and regulations, and an additional reserve flow capacity means the system can even cope with unexpectedly large surge transients.